Galvanized Steel Stress Corrosion Cracking Testing

Preventing Corrosion Under Insulation V. Mitchell Liss Engineering consultant, La Grange, TX Category: Design/Fabrication Summary: The following article is a part of the National Board Technical Series. This article was originally published in the January 1988 National Board BULLETIN. (6 printed pages) Galvanic corrosion, alkaline acidic corrosion, and stress-corrosion cracking have all been known to happen in certain conditions. Here are ways to reduce attack. Although the extent and resultant cost of corrosion under insulation (CUI) are not known exactly, J. Delahunt in 'Corrosion Control Under Thermal Insulation and Fireproofing' 1 shows the seriousness of the problem by presenting case histories.

These cover deep pitting, as well as general corrosion, that have occurred on galvanized steel tanks under 12-year-old polyurethane foam. Delahunt advises that metal loss can be the least of the problem. For example, an eight-inch carbon steel pipeline carrying heavy fuel oil was insulated with calcium silicate block and protected with a metal weather jacket.

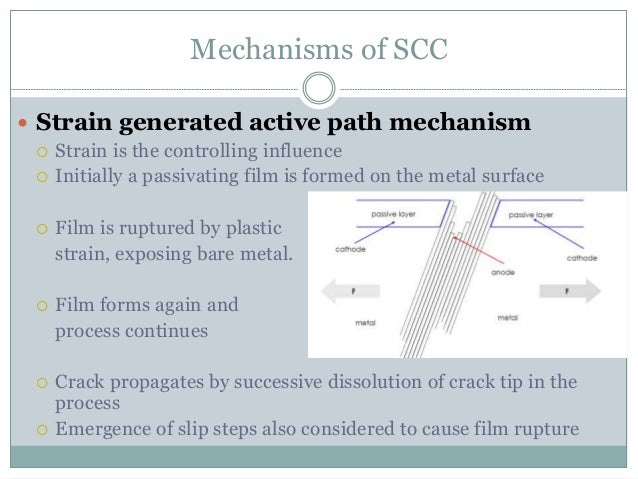

Protective coatings can be metallic, such as the galvanized steel shown below, or they can be applied as a liquid 'paint.' Most of the research and testing of protective coatings at the Kennedy Space Center is related to paint-like protective coatings. Filiform corrosion occurs underneath protective coatings. Loss of mechanical strength with little metal loss; the damage is not obvious to casual inspection and the stress corrosion cracks can trigger mechanical fast.

Find great deals on eBay for cyberlink powerdvd 17 ultra. Shop with confidence. Skip to main content. Cyberlink Upgrade to PowerDVD 17 Ultra from 12/13/14/15/16 Disc. Or Best Offer. 7 product ratings - ️ CyberLink PowerDVD Ultra 18 Full Version 🔐 Full Lifetime Instant Delivery. Cyberlink powerdvd 12 full version. CyberLink PowerDVD Ultra 15 Serial Number: CrackSoftPC.Com – CyberLink PowerDVD Ultra 15 Serial Number is very famous software. It was developed by Cyberlink. And it’s release date is 2 November 2015. It is the best media player for windows. This is single click downloadable offline setup of CyberLink PowerDVD Ultra latest version, to play you HD Videos with multiple format support. CyberLink PowerDVD Ultra v15.0 Product Review: CyberLink PowerDVD Ultra is a multimedia playback product with amazing features and support for multiple formats.

The pipe corroded, resulting in a leak. The oil was ignited and a large fire ensued, causing hundreds of thousands of dollars in damage to process equipment.

Types of Corrosion Under Insulation By understanding the types of corrosion that can occur under insulation, the proper materials and construction can be employed to prevent them. Intruding water is the key problem in CUI. Special care must be taken during design not to promote corrosion by permitting water to enter a system either directly or indirectly by capillary action.

Moisture may be external or may be present in insulation. Corrosion may attack the jacketing, the insulation hardware, or the underlying piping or equipment.

Depending on other factors, chloride, and galvanic, acidic or alkaline corrosion may occur. Galvanic corrosion generally results from wet insulation with an electrolyte or salt present that allows a current flow between dissimilar metals (i.e., the insulated metal surface and the outer jacket or accessories).

The extent and severity of the attack on the less noble metal depends not only on the difference in potential of the two metals, but also on their relative areas. The complete galvanic series and the voltage potential for each metal or alloy appear in handbooks and other standard references. The mechanism of galvanic corrosion is detailed by G.

Butler and H. Ison in 'Corrosion and Its Prevention in Waters.' 2 Alkaline or acidic corrosion results when an alkali or acid and moisture, are present in certain fibrous or granular insulations. For hot service above 250 o F, most of the water is driven off. This water vapor may condense at the edge of the insulation, and dissolve the alkaline or acidic chemicals there, resulting in corrosion of the aluminum or steel jacketing. Some alkaline waters with aluminum produce etching and pitting.

Ceramah-ceramah Ustadz Abdul Somad sangat digemari karena dijelaskan dengan begitu cerdas dan lugas. Download Buku 37 Masalah Populer Karya Ustadz Abdul Somad Buku 37 Masalah Populer merupakan salah satu buku yang paling banyak dicari saat ini. Download novel dewasa pdf terjemahan fiqh.

Pitting can be severe, especially when chloride ions are present. Insulating cement may also contain alkaline chemicals and water (while the cement is still drying). Below 250° F, an alkaline water may cause corrosion if the substrate or insulated surface is stainless steel, copper, brass or aluminum. Steel would normally not be affected in the time needed for the cement to dry. Fresh, potable water is recommended when mixing insulating cement. Delahunt reported on leaching tests performed on polyurethane foam insulation containing fire retardant chemicals (i.e., brominated or chlorinated compounds). Distilled water was used, and aggressive acidic solutions were formed.